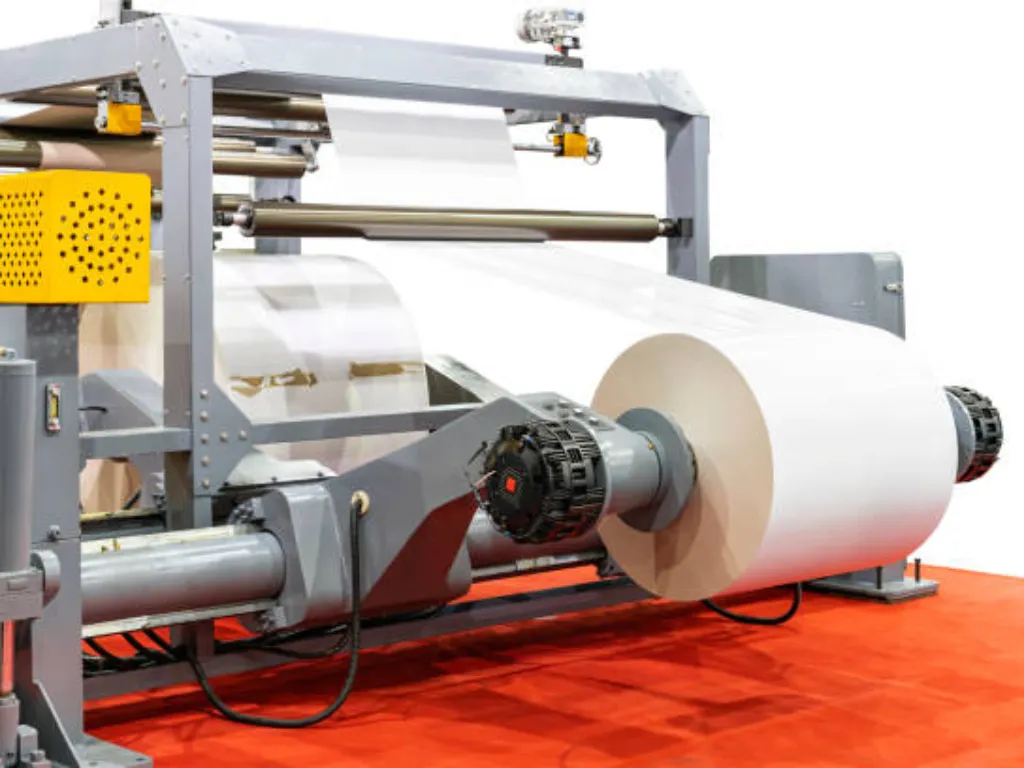

Slitting machines that combine innovation with robust engineering designs represent the pinnacle of modern industrial technology, delivering exceptional performance, reliability, and efficiency across diverse applications. These advanced machines are engineered with cutting-edge features that enhance precision, speed, and operational versatility, meeting the ever-growing demands of industries such as packaging, printing, textiles, and manufacturing. By integrating innovative technologies like automated controls, high-precision blades, and intelligent monitoring systems, these slitting machines ensure consistent and accurate cutting results every time, minimizing material waste and boosting overall productivity. One of the key strengths of these machines lies in their robust engineering design. Built with durable materials and reinforced structural components, they offer outstanding stability and longevity even in the most demanding production environments. This strength not only contributes to their excellent cutting accuracy but also reduces downtime and maintenance costs, creating a reliable workflow that maximizes operational uptime. The rugged design ensures that the machines withstand continuous heavy-duty use without compromising on performance, making them a smart investment for businesses seeking both quality and durability.

Innovation in slitting machine also extends to their user-friendly interfaces and adaptable configurations. Modern machines come equipped with intuitive touchscreen controls, allowing operators to easily set parameters, monitor performance, and adjust settings on the fly. This flexibility means that these machines can handle a wide range of materials and thicknesses, from delicate films and foils to tougher substrates like metal sheets or cardboard. The ability to swiftly switch between different jobs without extensive retooling significantly improves production efficiency and responsiveness to market demands. Moreover, the integration of smart sensors and real-time diagnostics elevates the operational intelligence of these slitting machines. Operators receive instant feedback on machine health, blade condition, and material alignment, enabling proactive maintenance and quick troubleshooting. This predictive approach helps avoid unexpected breakdowns and extends the lifespan of critical components, ultimately reducing overall costs and increasing return on investment.

Additionally, many machines support connectivity options for Industry 4. 0 applications, allowing seamless integration into automated production lines and data-driven KETE manufacturing environments. The environmental benefits of these innovative slitting machines should not be overlooked. Their precise cutting capability reduces material wastage, contributing to more sustainable manufacturing practices. Energy-efficient motors and optimized power consumption designs also help lower operational costs and carbon footprints, aligning with modern businesses’ goals for greener production. In conclusion, slitting machines that marry innovation with robust engineering designs are transforming industries by delivering unmatched accuracy, durability, and operational intelligence. These machines empower manufacturers to enhance product quality, streamline production processes, and adapt quickly to changing market needs. With their combination of advanced technology, sturdy construction, and ease of use, they represent a forward-thinking solution that drives growth, efficiency, and sustainability in today’s competitive industrial landscape.

Comments are closed, but trackbacks and pingbacks are open.